GroPoint Lite Support Resources

Documentation

Specifications

Analog

Digital

| Moisture | |

|---|---|

| Measurement range | 0% to 100% of VMC |

| Accuracy | ±2.0% * |

| Precision | < 0.2% |

| Electrical | |

| Interface | 0-5 mA, 4-20 mA |

| Connection | Bare wire (Optional EN3 3-pin IP66/IP68 rated environmental connector) |

| Warm-up time on power up | |

| Input voltage | 6 to 14 VDC max. 18 VDC |

| Current consumption | 0-5 mA: 18 mA (nominal), 25mA (max) 4-20 mA: 30mA (nominal), 50 mA (max) |

| Environmental | |

| Operating temperature | -20°C to 70°C (-4°F to 158°F) |

| Storage temperature | -40°C to 85°C (-40°F to 185°F)Physical |

| Physical | |

| Dimensions | 19.6 cm x 2.0 cm x 0.56 cm (7.7” x 0.8” x 0.2”) |

| Weight | 272 g (0.6 lb.) |

| Cable weight | 38 g per m (0.42 oz. per foot) |

| Standard cable | 5 m (16.3 ft.)3xAWG22 dual-shielded, twisted pair, rated for direct burial |

| Warranty | 1-year limited parts and labour |

| Moisture | |

|---|---|

| Measurement range | 0% to 100% of VMC |

| Accuracy | ±2.0% * |

| Precision | < 0.2% |

| Temperature | |

| Measurement range | -20°C to +70°C (-4°F to 158°F) |

| Accuracy | ±0.5 °C |

| Electrical | |

| Interface | SDI-12, RS-485 |

| Connection | Bare wire (Optional EN3 4-pin IP66/IP68 rated environmental connector) |

| Warm-up time on power up | |

| Input voltage | 6 to 14 VDC max. 18 VDC |

| Current consumption | Quiescent: Active: 15-35 mA |

| Environmental | |

| Operating temperature | -20°C to 70°C (-4°F to 158°F) |

| Storage temperature | -40°C to 85°C (-40°F to 185°F)Physical |

| Physical | |

| Dimensions | 19.6 cm x 2.0 cm x 0.56 cm (7.7” x 0.8” x 0.2”) |

| Weight | 272 g (0.6 lb.) |

| Cable weight | 38 g per m (0.42 oz. per foot) |

| Standard cable | 5 m (16.3 ft.)4xAWG22 dual-shielded, twisted pair, rated for direct burial |

| Warranty | 1-year limited parts and labour |

FAQ

+ SDI-12

- General

Are GroPoint Lite soil sensors compatible with all data loggers?

GroPoint Lite will work with virtually any data logger. Just ensure your data logger will handle the output of your GroPoint Lite sensor whether it's SDI-12, RS-485, 0-5mA or 4-20ma. If you are looking for a datalogger, check out GP-BTDL Bluetooth SDI-12 Data Logger

Can a GroPoint Lite soil sensor be used as a portable solution?

No, GroPoint soil moisture sensors are meant to be used on a permanent or semi-permanent basis. There should be minimal disturbance of the surrounding soil for proper accuracy.

What is the area of influence, or measurement volume, for the sensor?

The GroPoint Lite measure the average volumetric water content along its active length about 15 cm (6″), which is 3 cm (1.25″) from the top and 2.5 cm (1″) from the bottom of the sensor, whether the sensor is installed vertically or horizontally. Under most conditions, the sensor’s active range extends about 10 cm (4″) out from the side of the sensor, and 2.5 cm (1″) from the tip.

I’m not in BC or Canada. Can I buy and obtain support for GroPoint products locally?

GroPoint has dealers in several international locations. You can find your local dealer on the Dealers page.

GroPoint soil probes and data loggers are also sold online and we offer several self-help support resources, as well as unlimited support via phone, email and online chat.

What measurement frequency do GroPoint soil moisture sensors operate at?

The GroPoint Lite family of sensors send TDT pulses with sub nanosecond rise times, around 500ps, so the frequency bandwidth exceeds 1-2 GHz.

What does my sensor's ID string mean?

013RIOTTECHGPLPTS036SN612345

allccccccccmmmmmmvvvxxxxxxxx

Where:

a = sensor address (0)

ll = SDI-12 compatibility (13 for V1.3)

cccccccc = company name (RIOTTECH)

mmmmmm = sensor model number (GPLPTS)

vvv = sensor version (036)

xxxxxxxx = serial number (SN612345)

- Communication & Configuration

What power-on delay time is needed for GroPoint SDI-12 sensors?

GroPoint Lite sensors need a minimum power-on delay of 350 ms before they will respond to a command.

Can you power GroPoint Lite SDI-12 sensors with a continuous 12VDC?

Yes, there is no problem continuously powering the sensors with 12V.

Does temperature come standard with the GroPoint Lite SDI-12 sensors?

Yes, the standard configuration for GroPoint Lite is with temperature sensing capabilities.

- Sensor Readings

Can damage to the housing affect my moisture readings?

Minor cosmetic damage to the polycarbonate housing will not impact soil moisture or temperature readings. However, significant damage, such as cracks or gouges, can interfere with moisture measurements. This is because larger damage reduces the material between the soil and sensing element, and can allow water to infiltrate between the housing and the epoxy encapsulating the sensor. For this reason, proper installation and extraction methods are essential to prevent housing damage.

Are GroPoint sensors affected by changes in temperature?

GroPoint sensors are minimally impacted by temperature changes, so you should not see significant variations in moisture readings due to temperature shifts affecting the sensor’s measuring circuit. However, be aware that the dielectric constants of water and different soil types can vary with temperature, which may influence moisture content readings under certain conditions.

How do I validate the readings from my GroPoint sensor?

Validation depends on whether the sensor is installed and your desired accuracy level.

Before Installation:

- Hand Grab Method (Least Accurate): Take readings while holding a sensor segment. Readings will fluctuate based on hand size and contact. Expect increases up to 20% or more. You can use a damp towel but ensure that it is thick enough and covering enough of the sensor body. Damp paper towel is not sufficient enough to get a reading.

- Water Immersion Method: Immerse the sensor in a large water container (minimum 15cm diameter). Readings increase segment-by-segment with immersion, reaching a maximum around 55-60% VMC.

- Sand Column Method (Most Accurate): Install the sensor in a capped PVC/ABS pipe (minimum 8cm inner diameter). Fill with sand, tamp, and saturate with water. Readings should stabilize around 33 %VMC, though results may vary depending on sand type and compaction.

After Installation:

- Water Pour Test: Pour a large bucket of water slowly around the probe's insertion point while monitoring readings. They should rise steadily, reflecting soil porosity, with segment readings increasing sequentially.

- Troubleshooting Low Readings: Rapid spikes followed by a rapid drop suggest air gaps around the sensor.

Consistently low readings could indicate the presence of rocks, stones, roots or other underground objects near the sensor body.

How do I interpret my sensor readings?

GroPoint soil moisture sensors measure in % Volumetric Moisture Content (%VMC), which represents the percentage of water volume in the soil. The interpretation of moisture values depends on several factors but specifically soil type and it's water-holding characteristics, and your crop type. Different soil types have distinct wilting points, field capacities and saturation points.

- Wilting Point: The soil moisture level at which plants can no longer extract water.

- Field Capacity: The amount of soil moisture retained after excess water has drained away.

- Saturation: The maximum amount of water the soil can hold.

To understand what your sensor readings mean for you, you should know roughly what your soil type is. This allows you to know whether your moisture content is in an acceptable range. For example, Sandy loam soils have a field capacity of approximately 21%VMC whereas sandy clay soils have a field capacity of approximately 33%VMC.

Different crops require a certain field capacity for optimal growing conditions. If you know your soil type and crop type, then you can figure out your optimal soil moisture range!

- Calibration & Accuracy

Can you explain your calibration process for the GroPoint Lites?

Our calibration process is extensive, involving multiple reference solutions with different dielectric constants in 6 inch diameter columns. Each segment is individually calibrated to match a reference % moisture content. The process is time-consuming but very accurate, and very repeatable against a reference.

Does it need to be calibrated for different soil types?

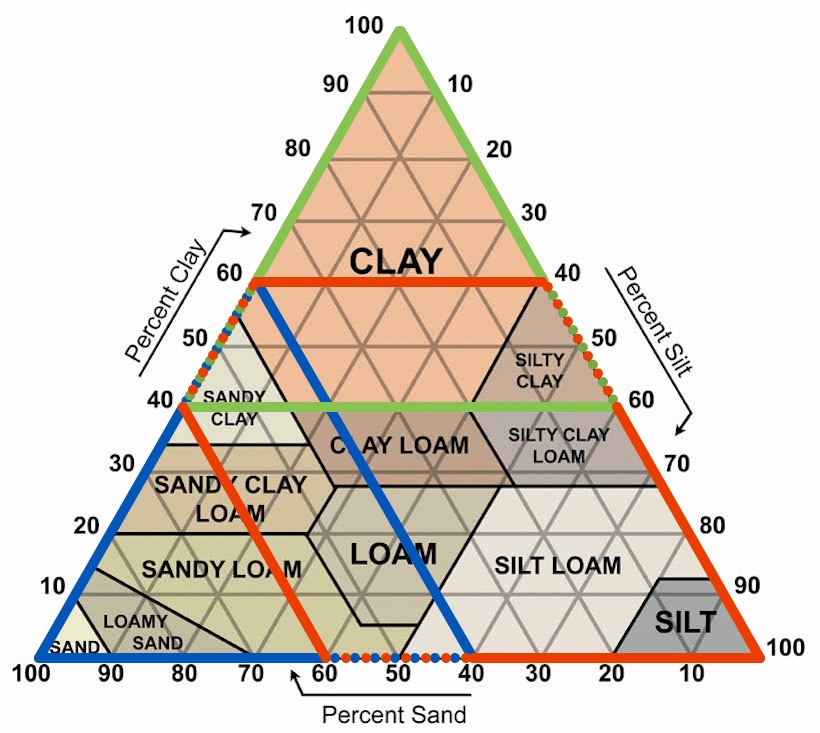

GroPoint soil probes are factory-calibrated for use in most soils and deliver optimal accuracy within 8-41% volumetric moisture content(VMC). There are also two other standard calibrations that can be used, which you can specify when you order. Below is an image of a standard soil texture triangle. By default, calibration is done for a wide variety of soil types represented by the

Red

area. You can also request that your sensor is calibrated for clay or highly saline soil (the

Green

area) or sandy soils (Blue).

For specific soil types, end customers can also perform their own custom calibration (see appendix C of the GroPoint Profile User Manual).

While the absolute VMC values may vary due to differences in soil composition, the relative changes detected by the sensor remain consistent across all soil types. For instance, a 5% VMC increase measured in sandy soil will correspond to a 5% change in clay, allowing for reliable tracking of moisture fluctuations regardless of soil type.

If I use a sensor calibrated for a different type of soil than I have, will I lose accuracy?

If you’re using a sensor with the wrong calibration, measurements will have a small absolute error, read either too high or too low by up to 4%.

Can soil specific calibrations be done?

RioT does not perform soil-specific calibrations, but customers can carry these out if desired. If the soil type is known, users can apply a third-order polynomial adjustment to the sensor’s calibration coefficients to create a soil-specific calibration. For details on this process, refer to Appendix C of the GPLP manual.

Alternatively, general corrections can be applied if you have sandy soil or clay/high-salinity soil (contact support@gropoint.com). Users can also adjust sensor data for soil conditions post-measurement using software like Excel.

My soil horizons span sandy, loamy and clay mixtures. Can each segment be calibrated differently to more accurately measure the different soil horizons?

Yes! Each segment can be calibrated for different soil horizons via SDI-12 extended commands entered through a small software utility.

What is TDT

5

? How does it differ from other soil measurement methods?

TDT

5

is a proprietary technology based on Time Domain Transmission (TDT), which is a refined version of Time Domain Reflectometry (TDR). TDT measures the time taken for an electromagnetic wave to propagate (travel) along a given length of a transmission line in the soil. Moisture in the soil changes the soil’s dielectric properties, so that the electromagnetic wave travels at different rates in wet soil compared to dry soil. This allows for the accurate determination of soil moisture content.

However, we add our own engineering designs that result in a less expensive, more robust and more accurate (with greater repeatability) sensor than with pure TDT alone. This enhances TDT in five (hence “TDT 5 “) key ways:

- Measures with an antenna 5 times longer than the physical length of the probe, which reduces the impact of noise, and provides an average across the entire length of each segment of the probe.

- Filtering 400,000 pulses for each measurement – boosts accuracy to ±2% and repeatability to < 0.2%

- Captures measurement in less than 100ms – reduces power consumption

- Embeds antenna and circuitry on a single board – dramatically reduces cost to manufacture

- Encases entire sensor in a durable, sealed polycarbonate housing – maximizes durability

Learn more about TDT 5 here.

What is the difference between TDT and capacitance methodologies for measuring soil moisture? Are there any distinct advantages of TDT over capacitance?

Capacitance probes set up an oscillating circuit that has a different frequency of oscillation depending on the moisture content, whereas TDT (Time Domain Transmission) measures the time taken for an electromagnetic wave to travel along a given length of a transmission line in the soil. Both are affected by the soil’s dielectric properties, so the frequency of oscillation (capacitance) or the travel time (TDT) is related to the moisture content.

One of the drawbacks of the capacitance method is that the frequencies involved are usually fairly low (less than 500kHz). If they weren’t, the current consumption (which is directly related to frequency, that is, higher frequency means higher current) would be fairly high. The issue is that at these relatively low frequencies the measurement is quite negatively affected by conductivity, which leads to a lot of variability in the readings (poor accuracy). TDT frequency bandwidths are much higher, on the order 500 MHz (i.e. 1000 times higher) and up. Therefore they are not nearly as susceptible to electrical conductivity.

An advantage of TDT is that antennas can be constructed that measure the soil moisture over a large area. This is exactly what permits the GroPoint Profile to measure soil moisture over the entire length of the probe, averaging each 15cm (6″) segment. Capacitance probes, because of their physical construction, will only provide point measurement (measuring only at the point where sensors are located).

Are there any environments or soil types I should avoid with my GroPoint sensors?

GroPoint sensors are designed for inorganic soils that become saturated around 45% VMC. The sensors accuracy starts to decline for moisture contents above 41% and has a max reading around 55-60 %VMC.

Environments that become saturated higher than this or that are very porous with air gaps are less ideal applications for GroPoint sensors. Such environments might include:

- Composts with larger particulate

- Rice paddy fields

- Very high salinity

- Peat

- Wetlands

If you are unsure whether your environment is suitable, contact sales@gropoint.com for advice.

Why are GroPoint soil moisture sensors so accurate? Most soil sensors I see are only accurate to 3%.

GroPoint soil moisture sensors feature an accuracy rating of ±2% (±0.02 m3m3) volumetric water content in soil, between the range of 8% to 42% VMC (this is the normal range for agricultural applications). We obtain this accuracy through a patented technique which improves the performance of the already reliable TDT method of soil moisture measurement. This patented technology is called TDT5.

While a < ±1% accuracy rating is achieved in controlled laboratory conditions, GroPoint soil moisture sensors are factory calibrated for most agricultural soils. In field applications, accuracy may slightly decrease due to the inevitable heterogeneity of soil texture, soil compaction, moisture and fluctuation in soil temperature. The accuracy may also decrease in difficult soil conditions (higher clay and salinity content). For these reasons we state a real-world accuracy of ±2%. In normal conditions, GroPoint soil sensors will maintain this accuracy from permanent wilting through field capacity in sandy loam through clay soils with less than 60% clay particles. Under moderately saline conditions, GroPoint soil sensors will maintain their accuracy up to 6 ds/m.

- Troubleshooting

Why are my sensor readings not as expected?

Unexpected sensor readings can result from several factors:

- Installation Settling Period: It can take several weeks for a sensor to provide accurate readings, depending on how it was installed and the level of soil disruption. To check soil contact, pour water over the sensor. If moisture readings spike quickly to 40-50%, this may indicate air gaps, and the soil might need more time to settle around the sensor.

- Soil Type Variability: Different soil types can impact sensor accuracy. Calibration adjustments may be necessary to account for variations in soil composition. This can be done in the sensor using custom soil calibration (see appendix C of the GroPoint Profile Manual) or in post processing.

- Obstructions in the Measuring Field: Rocks, large roots, or any object within six inches of the sensor can interfere with readings by affecting the moisture levels in the sensor’s field of influence. If you suspect there may be large roots or you have rocky soil, you can try moving your sensor to a new location.

- Improper Installation: Installation errors can create air pockets around the sensor, causing water to flow around rather than through the soil, leading to irregular readings. Review proper sensor installation techniques to assistance.

- Sensor Malfunction: In rare cases, if the readings seem unrealistic or the sensor fails to respond to changes in moisture levels, there may be a technical issue. If this occurs, contact support at support@gropoint.com.

What should I do if my sensor is not communicating, or the communication is intermittent?

- Check Sensor Connections: Ensure the sensor is securely connected to your data logging equipment. Verify that all wires are properly connected and, if a connector is used, make sure no wires have come loose.

- Inspect the Sensor Cable: Look for any damage to the cable, which could be caused by rodent activity or general wear.

- Verify Connector Wiring: If a connector is attached, confirm that the wiring is correct.

- Ensure Proper Wiring to Data Logger: Double-check that the sensor is correctly wired to your data logging device according to the equipment’s specifications.

- Confirm Power Supply: Check that your data logger’s battery is charged and that the sensor is receiving a consistent 12V power supply. When the sensor starts a measurement, a brief current spike occurs. If the power supply or connection cannot handle this current spike, the sensor supply voltage may drop low enough to cause the sensor to reset. If this happens, only the sensor address will be returned for the D0! get data command, without any data.

- Verify Sensor Address: Make sure you are using the correct address for commands; sensors are shipped with a default address of 0. Use the ?! command to determine a sensor’s address (can only be sent when there is just a single sensor connected).

- Set Unique Addresses for Multiple Sensors: If you have multiple sensors connected, you must ensure each sensor has a unique address to avoid communication conflicts.

- Send SDI-12 Commands Manually: To test communication, send the command aI! (where a is the sensor address). If the sensor is communicating, it will return an ID string similar to 013RIOTTECHGPLPTS035SN600000.

- Contact Support if Needed: If issues persist, reach out to support at support@gropoint.com for further assistance.

+ 4-20mA

How does the output current relate to soil moisture readings?

The GroPoint Lite 4-20mA Analog sensor outputs 4-20mA where 4mA represents 0% volumetric moisture content (VMC) and 20mA represents 50%VMC.

How long should I wait to after powering on the sensor to take a reading?

You should 100ms after powering the GroPoint Lite 4-20mA to sample the output.

What is the power supply range?

The operating voltage is 6 to 14 VDC with an absolute maximum of 18 VDC.

How do I convert the output from current to voltage?

To convert the output from current to voltage, you will need to connect a resistor between the sensor output and the ground. This resistor is called Rsense in the circuit diagram below and the resistor value depends on what you want the voltage range to be.

*Note: the optional filter reduces signal noise. This filter may already be built into your measuring device.

For example, if you want your voltage range to be 0-5 VDC max, then you would choose the closest standard resistor size to 250 ohms. You will then need to find the minimum supply voltage required for the sensor, to do this you will need the maximum output voltage produced with your given resistor value and the compliance voltage of the sensor which is greater than or equal to 3 VDC. See sample calculation below:

+ Installation

How do I properly install my GroPoint Lite sensor?

The GroPoint Lite sensors should be installed vertically into the ground. Avoid digging a hole if possible to minimize soil disturbances, the design of the sensor body allows you to easily push the sensor into the ground. Do not apply excessive force to the top of the sensor. If you have to use a hammer to help install the sensor, only use a dead blow hammer and use gentle taps.

Why is proper sensor installation important?

Proper installation is crucial for several reasons:

- Reduces Risk of Damage: Proper techniques help prevent damage to the sensor, especially with longer probes. Damage caused to the sensor during installation is not covered under warranty.

- Minimizes Soil Disturbance: Careful installation minimizes disruption to the surrounding soil, preserving natural conditions.

- Prevents Mixing of Soil Layers: Proper installation avoids unintentional mixing of soil layers, which could affect sensor readings.

- Preserves Soil Structure and Water Flow: Maintaining the natural soil structure ensures that moisture moves as it would naturally, allowing for more reliable measurements.

- Speeds Up Accurate Operation: With correct installation, the sensor reaches stable, accurate readings more quickly.

How do I properly remove my GroPoint Lite from the ground?

To safely remove your GroPoint Lite, avoid pulling from the cable or cap, as this could detach the cable from the electronics or pull the cap off the sensor housing. Begin by digging around the sensor to expose enough of the blue housing for a secure grip. Once you have a firm hold on the housing, pull the sensor straight up.

How deep in the soil should the GroPoint Lite be placed?

These sensors are intended to have the top of the probe near the surface of the soil with the length of the probe determining the lowest depth of the soil moisture and temperature points.

How does soil disturbances affect soil moisture measurements?

Soil disturbance, such as compaction or mixing of soil layers, alters natural soil properties like structure and porosity. This can skew soil moisture data by changing how water moves through and is retained by the soil. In disturbed soils, water may either infiltrate too quickly or be blocked from reaching deeper layers, leading to inaccurate readings.

What is the impact of soil compaction on soil moisture?

Compacted soil has reduced air-filled pore spaces, which limits water infiltration and retention. This can result in lower accuracy of moisture measurements since the soil may hold less water than it would in its natural, undisturbed state. Compaction can also impede root growth and nutrient cycling, further altering moisture dynamics.

How does mixing soil horizons affect moisture readings?

When soil horizons (layers) are mixed during installation, it changes the natural arrangement of soil textures (e.g., sandy vs. clayey layers), which can impact how water moves through the soil. This mixing can cause sensors to record inaccurate moisture levels because the hydraulic properties of the soil are altered.

Why is it important to minimize soil disturbance during sensor installation?

Minimizing soil disturbance ensures that moisture readings reflect the natural soil environment. Disturbances like bore holes or improper repacking of soil around sensors can create air pockets or preferential water pathways, leading to false moisture readings. Using the GroPoint Pilot Rod can mitigate these effects because it matches the sensors profile for minimal soil disruption.

What is the maximum length of cable that can be used with the sensor?

For SDI-12 sensors, according to the SDI-12 specification, the combined length of all sensors connected to a data logger cannot exceed 610 m (2,000 feet). So one sensor with a 610 m cable or 10 sensors each with a 61 m cable.

For analog sensors, the maximum length is 305 m (1,000 feet).

It should be noted that the longer the cable is, the more susceptible the sensor is to catastrophic damage/failure due to increased voltage spikes from lightning strikes. A long cable becomes a very large antenna to amplify the voltage. Cable should be buried wherever possible.

The minimum wire gauge when using a cable approaching the maximum should be 20 AWG.

If you are interested in getting rid of the cable, check out this link. https://www.gropoint.com/products/wireless

Can the sensor cable be buried, and is it durable enough to be left exposed on the surface of the ground?

GroPoint sensors are furnished with a high quality cable suitable for direct burial or exposure to direct sunlight. It is resistant to damage from insects, abrasion and normal environmental exposure. However, mechanical damage from hoes, coyotes, gophers, other animals, and cultivators can easily cut this cable. Any problem with this sensor will most likely be due to damage to the electrical cable. To prevent damage, it is strongly recommended that the cable be installed in 3/4-inch electrical conduit. This size conduit is required to accommodate the passage of the plug connector.

Do GroPoint sensors need to be removed during winter?

GroPoint sensors do not need to be removed from the ground during winter. However, it is recommended to protect the cables from potential damage by rodents and other animals during this time.

How does the GroPoint Lite hold up to chemicals in the soil or different pH’s?

GroPoint sensor housings are made of polycarbonate which is resistant to a wide range of chemicals found in organic soils, acids and bases. If you are concerned whether the sensor integrity will hold in your environment, check the chemical compatibility charts for polycarbonate.